The weight of a smartphone is a technical detail that is often provided by manufacturers, but it usually only takes into account the mass of the device at the end of its manufacturing process, and not all the materials necessary for its design.

Because if we decide to calculate this data, we significantly exceed 171 grams on the iPhone 15. The association SystExt (Extractive Systems and Environments) estimates that our devices are made up of 65 to 80 different components.

But not all of these materials are used in the same way. Not surprisingly, the most common element in a smartphone is plastic. On an “average” device, it represents 17% of the total composition. Next we find the materials that were used to construct the screen (specifically the glass plate). Together, they account for 32% of smartphones.

Finally, the remaining 45% is occupied by various metals. There are 53 in total (including 12 important ones). Iron is the most abundant metal in the smartphone, weighing almost 16 grams. Far back we also find much more noble (and expensive) metals such as gold (0.017 g) and palladium (0.001 9 g).

Our smartphones are also made of magnesium (7 grams) or aluminum (7 grams). In these same proportions we find two rather rare and expensive metals, copper and cobalt which both weigh almost 6 grams in our smartphone.

Metal mining, a challenge for the planet

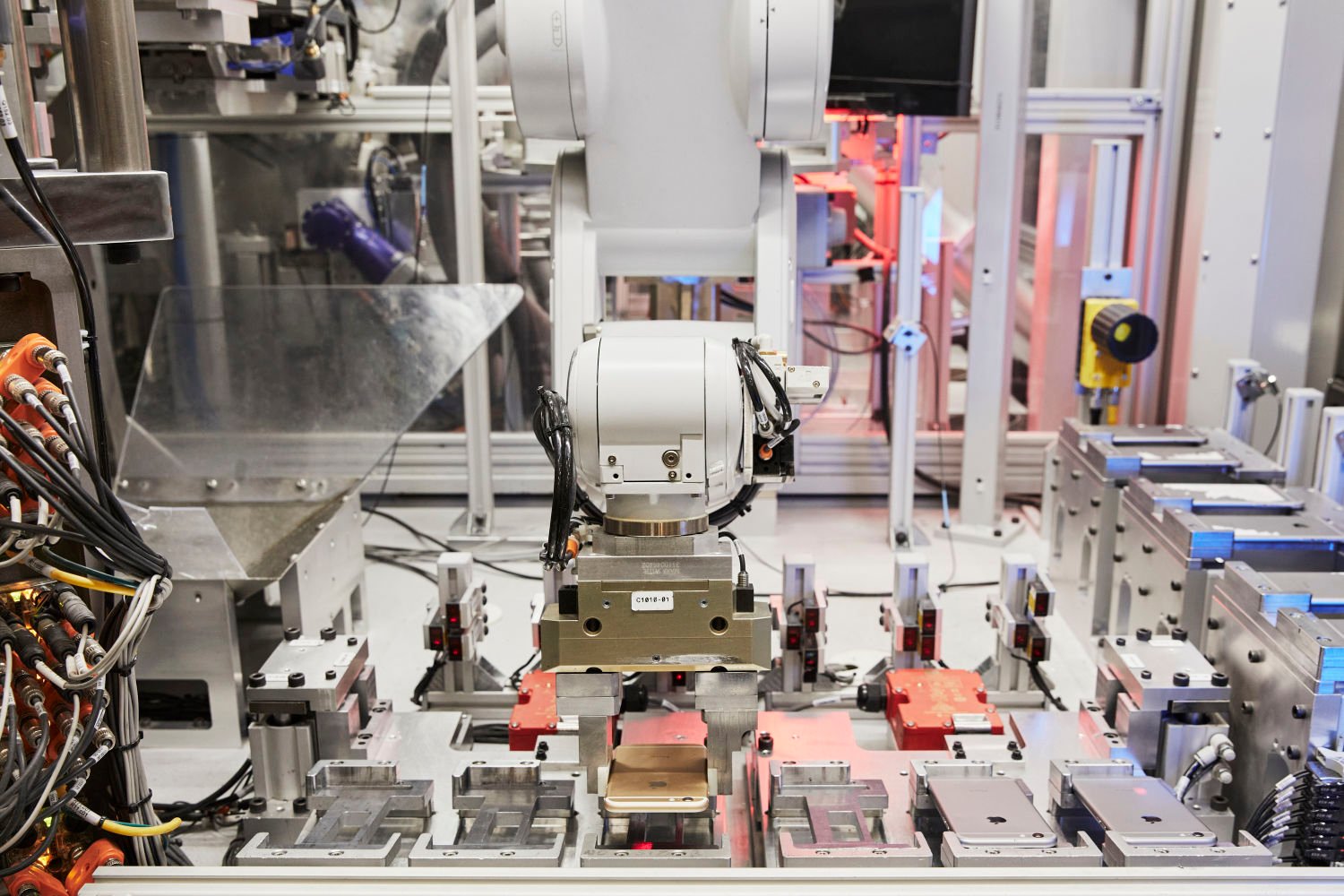

But extracting so many different metals is anything but easy. For that matter, ADEME estimates that a smartphone actually weighs 200 kilograms. In fact, it is necessary to mine this amount of rock to obtain enough precious metals to restore one smartphone.

According to the founder of the Green IT collective, Frédéric Bordage, we can easily imagine the price of an electronic device based on its weight. Between the final weight of the device and the amount of rock needed to manufacture it, he established a proportionality ratio of 500. In other words, one kilogram of computer would need 500 kg of raw rock to be produced.

The issue of smartphone recycling

Faced with this ever-increasing need for raw materials (the number of components in our smartphones has increased from 30 to 70 in 10 years), one solution presents itself as the most ethical: recycling our old devices. But here again the reality may be less beautiful than expected.

Indeed, and as the SystExt report explains very well, organizations responsible for the recycling of electronic devices are subject to the current standards regarding WEEE (Waste Electrical and Electronic Equipment). As such, they need to preserve a certain portion of the materials available in the smartphone to restore another.

A grim reality

But in reality, this batch of materials was not chosen by chance. As the SystExt association explains, recycling companies always focus on the same elements, gold, cobalt and copper. These three metals are actually the most profitable to recycle because they are very expensive to purchase. As for the rest of the device, everything can go in the trash.

According to a UN report, the share of recycled WEEE today is less than 50%. Designing a smartphone made from 100% recycled materials is nothing more than a commercial dream. In order to limit as much as possible the extraction of the materials needed to manufacture a smartphone, it is better to focus on second hand appliances and repackage it.